A machine that can effortlessly reduce cycle time without changing the machining conditions or loader speed.

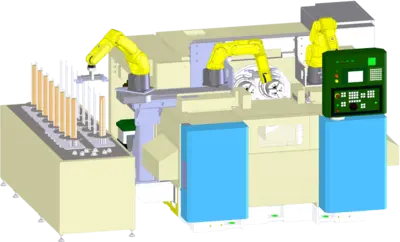

This 4-Spindle 2NC slide (4-spindle 2-turret lathe) can significantly reduce both the idling time and cycle time by cutting and loading/unloading the workpiece at the same time.

01

While the 1st and 2nd spindle are machining, the 3rd and 4th spindle are loading or unloading

▶Machining and workpiece loading/unloading are performed at the same time to achieve an effective loading time of zero seconds!

02

There are four chucks so all four operations (Operation 1 (OP1), Operation 2 (OP2), inversion, and workpiece attachment) are gathered on a single machine and performed at the same time.

A lathe with a high operation rate close to 100% that is always creating chips, this significantly reduces the cycle time and improves productivity!

03

The spindle for loading and unloading the workpiece is exposed outside the partition door. The machine design enables easy chuck exchange and manual workpiece loading/unloading.

04

Automation is achieved with zero robot space because the robot can be mounted on the machine.

Loading the robot on the slide rail provides a stroke equivalent to a gantry loader.

We use cookies to improve your experience. Privacy Policy.